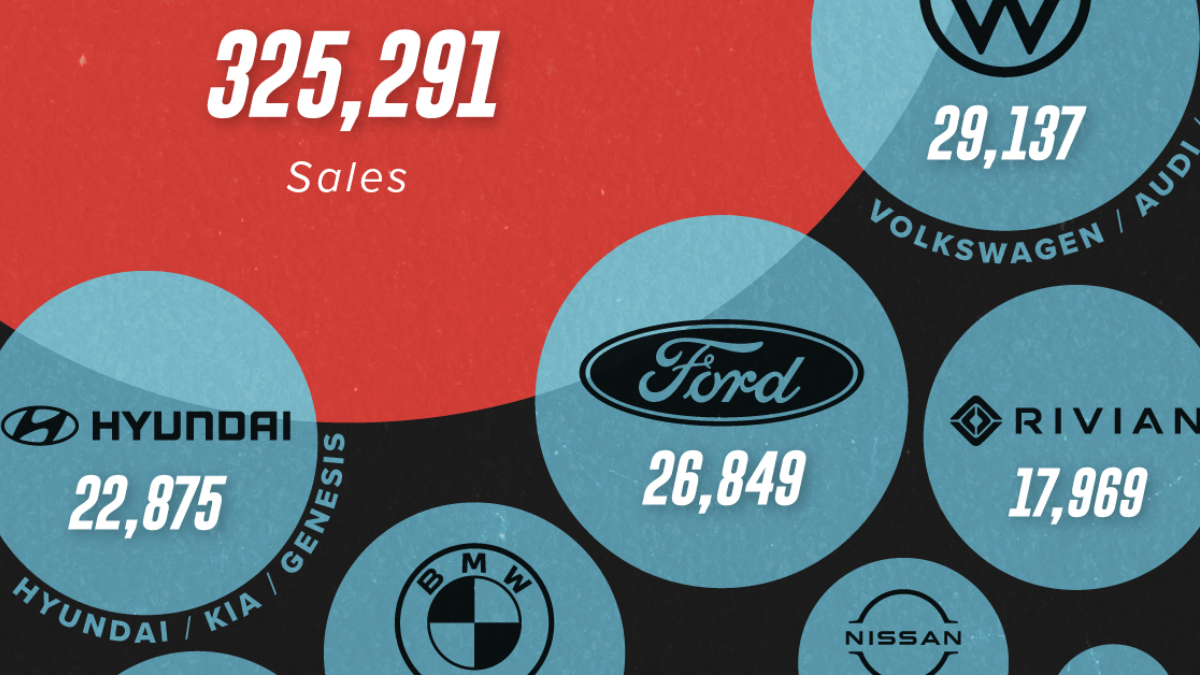

Graphical Representation of Electric Vehicle Sales in the United States during the First Half of 2023

This post was first published on Elements. Every other week, subscribers to the free mailing list receive stunning visualizations on natural resource megatrends directly in their inbox.

The composition and chemistry of an electric vehicle (EV) battery pack can determine its cost. The costs of battery cells on popular electric vehicles are highlighted in this graphic, utilizing data sourced from Benchmark Minerals Intelligence.

Size Matters

Replacing batteries in electric vehicles can come as a surprise to many owners due to the high cost involved. The expense of a fresh lithium-ion battery pack can vary greatly depending on the make and model of the automobile, with some costing as much as $25,000.

| Vehicle | Battery Type | Battery Capacity | Battery Cost | Total Cost of EV |

|---|---|---|---|---|

| 2025 Cadillac Escalade IQ | Nickel Cobalt Manganese Aluminum (NCMA) | 200 kWh | $22,540 | $130,000 |

| 2023 Tesla Model S | Nickel Cobalt Aluminum (NCA) | 100 kWh | $12,030 | $88,490 |

| 2025 RAM 1500 REV | Nickel Cobalt Manganese (NCM) | 229 kWh | $25,853 | $81,000 |

| 2022 Rivian Delivery Van | Lithium Iron phosphate (LFP) | 135 kWh | $13,298 | $52,690 |

| 2023 Ford Mustang | Lithium Iron Phosphate (LFP) | 70 kWh | $6,895 | $43,179 |

| 2023 VW ID.4 | Nickel Cobalt Manganese (NCM622) | 62 kWh | $8,730 | $37,250 |

Several factors contribute to the cost of an EV battery pack, including production expenses, packaging complexities, supply chain stability, and raw material costs. However, chemical composition is one of the primary factors that can shape the price of an EV battery pack.

Most lithium-ion batteries use graphite as the standard material for their anodes.

The cathode’s mineral composition is what typically undergoes changes, with lithium and other minerals like nickel, manganese, cobalt, or iron being included. This particular composition plays a critical role in determining the battery’s capacity, power, safety, lifespan, cost, and overall performance.

On average, the cost per kilowatt-hour (kWh) for lithium nickel cobalt aluminum oxide (NCA) battery cells stands at $120.3, while lithium nickel cobalt manganese oxide (NCM) comes in slightly lower at $112.7 per kWh. These battery cells contain substantial amounts of nickel, which enhances their energy density and enables them to achieve longer ranges.

Lithium iron phosphate (LFP) batteries are a more cost-effective option as compared to cobalt and nickel-based variants. The average price of LFP battery cells is around $98.5 per kWh. Although they offer lower specific energy, they are ideal for standard or short-range electric vehicles.

Which Battery Dominates the EV Market?

According to recent statistics, NCM batteries have emerged as the clear leader in the battery market, commanding a significant 58% market share in 2021. LFP and NCA batteries closely followed with a market share of 21% each.

According to predictions, the market share of LFP is expected to nearly double by 2026, reaching 38%. According to predictions, the market is set to be dominated by NCM, accounting for 45%, while NCA is expected to decrease to only 7%.

Also Read:

- Explore the Most Polluted City in Florida!

- Electricity prices have gone up, regardless of Contract agreements

- After 14 hours in three emergency rooms, a woman plans to buy the ring she couldn’t remove.

- Unused equipment worth over $780K found in closed Rikers Island facility with secret lounge.